The Viterra Cascadia Terminal project comprised removal of an existing 300 metre bridge built in 1922. For nearly a century, this bridge carried domestic cold water, medium pressure gas and high voltage electrical services between the original Viterra plant and above 11 railroad tracks. NDY was contracted to design the gas and water services in a large 1,350 mm diameter tunnel to run below the existing rail tracks. This involved considerable stakeholder engagement and approval from the City of Vancouver, CP Rail and the Port of Vancouver.

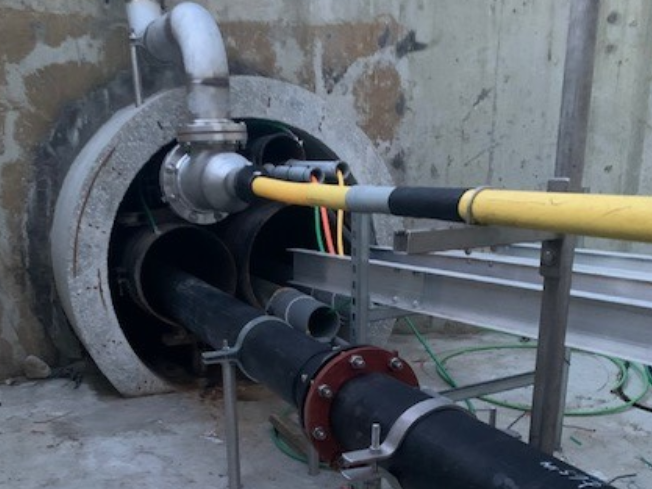

NDY completed the design of 8 inch DCW, and 2 inch diameter GAS in 1350 mm HDD tunnels below 11 railroad tracks, which replaces the bridge and includes services for sub-station and switch-gear building. Our team is renowned for working with different code bodies, municipalities and corporations to achieve success with building services on similar industrial projects.

A key challenge for the team was the series of variations to the initial design. The original design was for a large human access tunnel; however, the final design involves a functional, compliant space and non-accessible tunnel. Throughout the design amendments process, our team brought in strategically important advisory and design services whilst collaborating with the owner’s senior engineering, construction and operations experts, as well as several contractors, consultants, and architects.

With the main tunnel’s north and south portal in flux for a number of years, NDY requested a ground-penetrating radar investigation to assist our plumbing experts in considering locations and potential solutions around existing water, power, fiber optic cable, and gas utilities.

This mapping enabled an in-depth understanding of the piping systems in the area, helping NDY study and coordinate services with the high-voltage electrical systems, electrical consultant, and owner to find installation paths which go to and from the substation room. The team provided a hazard analysis for the gas system and recommendations for installation of gas detection, natural gas shutoff valve, and earthquake shutoff valve. The primary purpose of the project was to ensure safety underground. In the event of an environmental catastrophe, these safety measures are designed to help prevent an emergency or send a warning and shut off gas valve to stop a gas leak (which might eventually damage the 12 tracks and fiber optic cables).

NDY provided the design and construction administration for supply, exhaust, heater, and filtration for the switch gear room in the terminal. In addition, our team completed prescriptive code analysis to demonstrate compliance with American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) energy standards required by the City of Vancouver building by-law. Our main activity on this front was to collaborate and assist other teams within the project.

NDY designed both a high-density polyethylene 8-inch diameter DCW and 2-inch diameter medium pressure gas pipes in the tunnel, to replace the aging services on the demolished bridge.