NDY has been working with The University of Queensland (UQ) to improve the lifts throughout their Brisbane campuses. They asked us to improve reliability and availability, reduce maintenance and strengthen infrastructure and technology for the future.

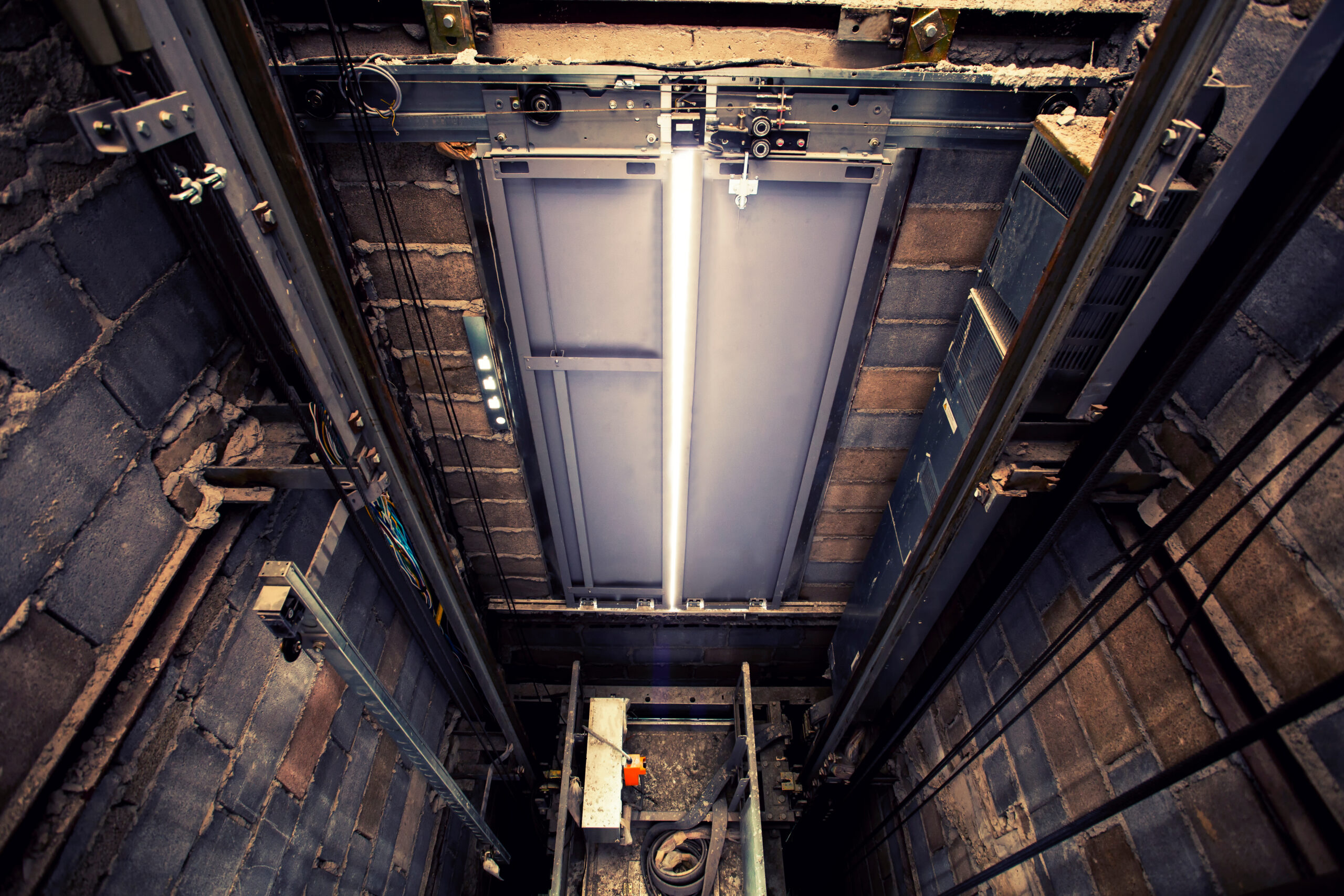

Our vertical transportation team started with an audit to determine the age and condition of the lift systems, type of technology installed, level of safety and accessibility compliance. We also highlighted areas of non-compliance with UQ design standards including minimum car dimensions. Our recommendations included upgrade options such as complete replacement, modernisation and modernisation with re-orientated car and counterweight.

Because new modern machine-room-less (MRL) systems often result in a smaller car and reduced accessibility provision and functionality, our design solutions focused on retention and modernisation of the existing hydraulic lifts for the Biological Sciences, Customs House, JKMRC and the Zelman Cowan buildings. The same approach was taken for the Banksia Building; as a large goods lift it required the size to remain the same, and a new MRL traction lift would have reduced both car size and rated load.

The Public Health Building stands out as an exception, undergoing replacement of the existing hydraulic lift with MRL lifts. Unusually, the shaft space allowed a new MRL without reduction in car dimensions while adding the benefit of increased car speed.

Undergoing a complete modernisation while retaining overhead traction systems, the existing lifts in the McElwain, Foxtail and Ritchie Research buildings met UQ standards, functionality and most accessibility requirements so were suitable for refurbishment without replacement.

The vertical transportation designs for the Skerman, Social Sciences and Axon buildings required enhanced modernisation solutions to ensure the existing lift car dimensions and orientation met UQ design guides and addressed functionality issues. The upgrade removed the old lift car and counterweight while retaining the machine room. A new car and counterweight were then installed in a new orientation, utilising the available shaft dimension to its fullest potential. An unusual approach that involved an extensive scope of works, the outcome improved the efficiency and usability of each building’s lifts.

While UQ design standards often call for machine room-based systems to reduce the amount of maintenance required at landing levels (i.e., in machine rooms), several projects focused on replacing existing lifts with MRL systems on the top floor. At Forgan Smith Tower, the lift machine room presented challenges with limited provisions for compliant maintenance access, posing safety concerns. To address this, the old lift was replaced with a MRL system, ensuring improved safety for maintenance activities and efficient operation.

The Steele Building’s lift 14 was an intriguing 1950s timber goods lift with manual side-opening doors. However, its outdated structure and non-compliant access to the lift machine room prevented it from meeting current safety codes. As a result, the lift, which was being used solely for materials, was completely removed. To enhance accessibility and ensure compliance, a new MRL system was installed in place of the old lift, offering a safer and more efficient solution.

Similarly, the Richards Building’s lift 15 was an interesting 1950s timber lift with manual vertical opening doors, but it lacked equal access for individuals with mobility impairments. As a material-only lift, it did not accommodate passenger transportation. To rectify these limitations and ensure safe access to the lift machine room, the old lift was entirely replaced with a new MRL system. Both lift 15 in the Richards Building and lift 14 in the Steele Building required custom solutions due to their limited shaft space, making the modernisation projects unique and tailored to meet specific needs.

We estimate the 9 buildings where we’ve been able to modernise existing lifts, rather than replace the lift system, will save UQ 54,000 kg of steel, the equivalent of 150,000 kg of CO2. Alongside increased accessibility, functionality and efficiency, the vertical transportation upgrades will make a huge impact in helping UQ achieve its mission of ‘delivering for the public good‘ and ‘purposefully investing in infrastructure [and] systems’.

Project Details

Services:

Vertical Transportation

Market Sector:

Education

Client: The University of Queensland

Contractor: TK Elevator

Value: Commercial in confidence

Completion: Ongoing