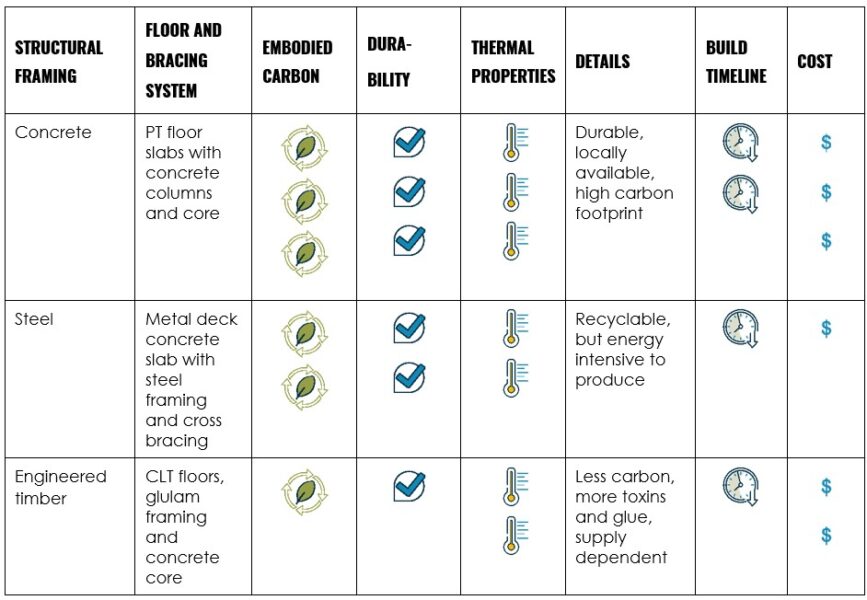

The choice of structural system in a commercial office is largely influenced by cost, architecture, construction timeline, design life and sustainability considerations. Comprehensive and accessible comparisons between structural options – such as steel framing with concrete slabs, engineered timber (glulam and CLT), or concrete – are critical for enabling a strategic decision-making process.

In this article, we offer a detailed comparison of 3 different structures:

- Concrete frame with post-tensioned (PT) floor slabs and a concrete core

- Steel frame with metal deck concrete slab, and steel cross bracing

- Engineered timber frame with cross-laminated timber (CLT) floors and a concrete core.

Concrete slab and frame construction

Steel-framed building with concrete slabs

Engineered timber construction

Case studies

- Steel framing suited to all building heights, One Queen Street, Auckland

- Timber framing suited for low to medium rise buildings, Murdoch University – Boola Katitjin Building, Perth, WA

- Concrete framing common for high-rise and heavily loaded commercial buildings, Rialto, Melbourne, VIC

The industry is shifting

In 2000, concrete and steel were the dominant structures:

- Concrete (~55%): the predominant material in global construction, due to its durability, availability and cost-effectiveness

- Steel (~25%): primarily used in commercial and industrial buildings, offering strength and flexibility for large-scale structures

- Timber (~20%): mainly used in residential buildings, particularly in regions with abundant forest resources.

In 2025, we’re seeing change:

- Concrete (~45%): the share of concrete has decreased. The industry is adopting low-carbon alternatives and incorporating recycled materials to reduce its carbon footprint.

- Steel (~30%): the use of steel has increased, driven by advancements in recycling and the development of high-strength, lightweight alloys.

- Timber (~25%): share has grown, particularly with the rise of engineered wood products like cross-laminated timber (CLT) and glulam which offer enhanced strength and sustainability.

Please note, these are approximate figures, based on our experience and the sources below.

Construction Materials Market Size, Share & Analysis 2033 Report / Construction Materials Market Size to Surpass USD 2.01 Tn By 2034 / Building Materials Industry Statistics: Market Data Report 2025

Understanding what’s behind your structural materials

Structural myths

Misconceptions frequently cloud judgments about structural materials. Clarifying these misconceptions ensures more balanced decisions that align with long-term project goals.

- Concrete, despite being perceived as resource-intensive, provides superior benefits in terms of longevity, thermal mass and lower maintenance requirements.

- Steel is often presumed to be unsustainable due to its manufacturing process, yet it offers significant recyclability advantages if corrosion protection measures are maintained correctly.

- Mass timber can be viewed as less durable or fire-safe, overlooking advancements that have enhanced its resilience in recent times.

Innovation in design

The commercial construction industry continues to evolve rapidly, driven by technology, the need to decarbonise and market trends. Prefabrication, modular construction and digital twins are reshaping project timelines and sustainability outcomes.

Mass timber construction – using glulam beams and CLT floors combined with a concrete core – exemplifies these trends, significantly reducing construction times and improving environmental footprint.

Staying abreast of these advancements is key to adopting sustainable, cost-effective and tailored buildings.

Project alignment

Evaluating structural choices requires careful analysis of how each system aligns with sustainability objectives, project timelines and cost parameters:

- Steel framing with metal deck slabs offers flexibility, rapid construction and reduced foundation loading, beneficial for projects with time constraints and complex site conditions.

- Concrete framing with post-tensioned slabs presents advantages in long-term durability, reduced maintenance and, potentially, lower lifecycle costs.

- Mass timber structures uniquely offer strong sustainability credentials, reducing carbon footprints and enhancing occupant wellbeing through biophillic design.

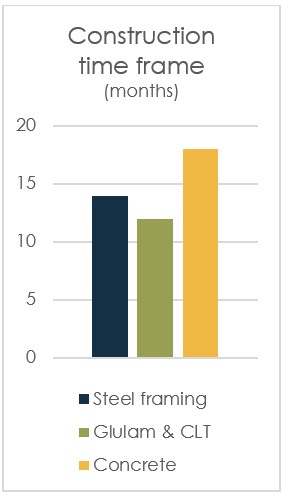

Construction timeframe

Indicative onsite duration to build an 8-storey commercial building

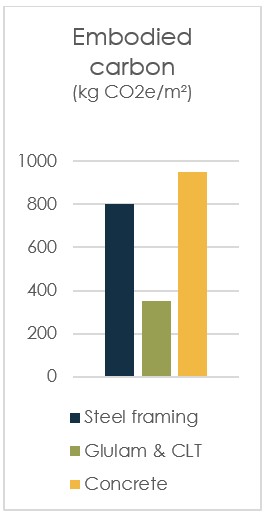

Embodied carbon

Primary structure materials, transport and manufacturing, excluding any architectural finishes

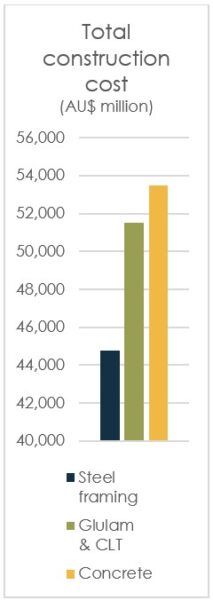

Total construction cost

Relative cost comparison of the 3 materials (GFA of 10,800 m2)

Foundation loading

A critical aspect often overlooked in structural system selection is foundation loading and the number of piles required.

- Concrete framing typically has the highest foundation loading, necessitating more extensive piling and foundation work, which increases both initial costs and construction complexity.

- Steel framing offers moderate foundation loads, requiring fewer piles compared to concrete, potentially speeding up foundation construction.

- Mass timber systems, with their inherently lighter weight, present significantly reduced foundation loads, thereby decreasing the depth of piles required and offering substantial savings in both foundation costs and construction time.

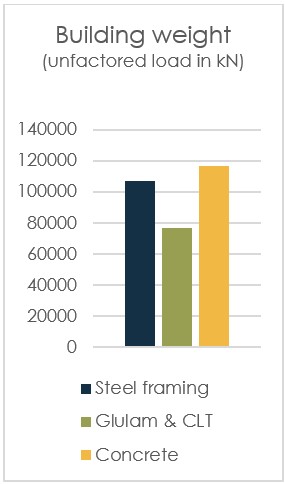

Building weight

Total unfactored load comparison in kN

Ultimately, making the right structural choice for a commercial office building hinges on an integrated approach that comprehensively evaluates each option’s impacts. A team can maximise project success by making informed decisions using accurate data. It’s also important to act on fact over misconception and align decision making with industry innovations.

Embracing a holistic view that considers lifecycle costs, environmental impacts and evolving technologies – aligned to your project priorities, timescale and budget – enables you to choose a structure aligned with your strategic objectives to deliver long-term value.